MAC Liquid Bullet Valve

Top up fluids with MAC Liquid Bullet Valve

Filling liquids with very precise repeatability? That's possible with the MAC Liquid Bullet Valve. The Liquid Bullet Valve is an electric solenoid valve that is suitable for precise dosing and filling liquids. This is possible for both small and large flows. Additionally, the innovative technology coming from the Bullet Valveis now used for the the fluid valve. That means that the switching times are both precise and repeatable. As a result, liquids are filled with exceptionally precise repeatability.

The history of the fluid valve

The MAC Bullet Valve (read more about the design) is equipped with flexible seals, making the valve suitable for aggressive gases and liquids. The D-rings have also been replaced by membranes and because of this, it's not possible to have liquid run out over the dynamic seal.

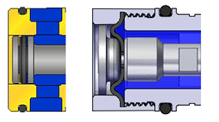

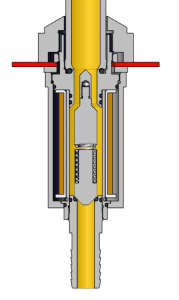

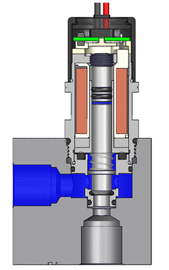

Figure 1: Left standard MAC Bullet Valve / Right Liquid Valve

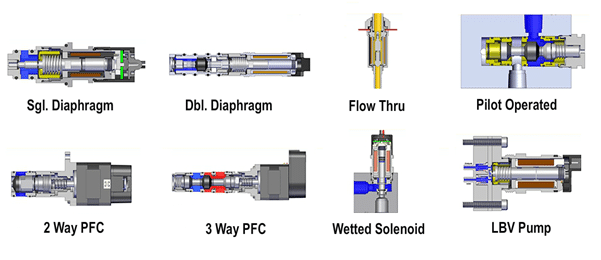

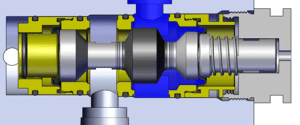

The MAC Liquid Bullet Valve is made up of modular solenoid valves, because each application has different requirements. Several variations of materials have been used for the valves. You can consider: stainless steel, plastic, brass and rubber seals, such as: NBR, Viton, Kalrez.

Various customer requests have resulted in many patented designs in terms of structure. Each design has its own qualities. We will describe the different types in more detail in this article.

Figure 2: Types of MAC Liquid Bullet Valve

Techniques MAC Liquid Bullet Valve

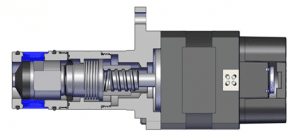

Single Membrane

The single diaphragm valve is equipped with a single diaphragm. The membrane protects the electrically switched part, preventing liquids from reaching the coil. The valve is balanced on the incoming side (see explanation here). . This allows the solenoid valve to dose precisely, independent of pressure variations in the liquid. In this way, the opening and closing times are not affected by pressure variations. This means that the time that the valve is open can be well controlled in case of pressure variations.

Depending on the wishes in the design, there can be no dead space in the exhaust. This makes it possible to dose ink, paint or bacteria-sensitive liquids. The dead space on the incoming side can also be manufactured to the absolute minimum.

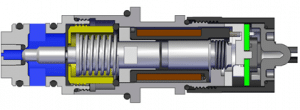

Figure 3: Cross-section of a single diaphragm valve

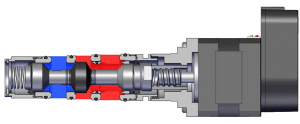

Double Membrane

The double diaphragm valve, which is used for example as a water valve, has replaced both d-seals with diaphragms. The valve is available in 2/2 and 3/2 function. A great advantage of this is that any arbitrary port can be used to connect the liquid. This is because all ports are balanced.

The miniature solenoid valve is usedfor filling or dosing in the 2/2 variant. In terms of direction, it can be both radial and axial. This makes the valve very flexible for installation in various configurations. Additionally, the valve is also used in the 3/2 variant for filling and emptying volumes. Think of a fixed volume that you fill and empty for the principle of a volumetric pump. Moreover, you can use a 3/2 fluid valve as divert or select valve.

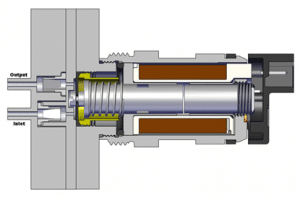

Figure 4: Cross-section of a double diaphragm valve

Flow Thru

The Flow Thru design has been developed for the laminar airflow. Most carbonated liquid valves are generally subject to turbulent flow. Because the friction and the bends have to go through the liquid.

Figure 5: Cross-section of Flow Thru

All contact surfaces are developed according to a smooth flow. The coil surrounds the liquid and moves the armature and the magnetic core in the center. The liquid flows smoothly through and passes the seat, into the bottle or glass. This principle ensures that no foam is created and thus a better end product is created. In addition, the valve has no dead spaces where the liquid can settle.

Pilot Operated

Electric solenoid valves have a limited stroke capability. This is due to the magnetic force that is generated and the required strong return spring. There is a possibility to create a stronger force through a higher absorbed power, but this usually causes heat in the liquid as well. Since sometimes a larger passage and precise filling quantity is required, MAC Valves has developed the Pilot Operated Liquid Bullet Valve. This valve is used, among other usage options, as a water valve for large flows up to 100 liters / min. The valve is controlled by a pilot air signal and returns to its original position with a return spring.

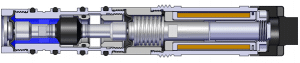

Figure 6: Section of Pilot Operated Liquid Bullet Valve

2-way PFC

PFC stands for Proportional Flow Control, a proportional flow controller or proportional flow controller. In the design, a scooter motor is attached to the doll. The puppet moves back and forth due to the movement of the scooter motor. The position of the stepper motor, in combination with the design of the Bullet Valve, provides the control.

Figure 7: Section of 2-way proportional flow controller

The needle has been developed in such a way to obtain an optimal flow and a good hysteresis. The PFC can be programmed with the supplied controller board by means of a 4-20 mA or a 0-10 V signal.

Feedback links are also possible, such as the help of a built-in optical encoder. In addition, the MAC Valves PFC is also available for compressed air, but it is most commonly used for electrically controlling liquid flows.

3-way PFC

The three-way PFC has the same construction as the two-way PFC. The three channels in the MAC Valves PFC ensure that there is a possibility to mix two flows properly.

Figure 8: Section 3-way proportional flow regulator

In this way, two liquids or one liquid can be mixed with air. Thus, the end product can be well concentrated at all times.

In addition, this principle can also be used, for example, in turbines that regulate the flow of the discharge and supply. This principle is also used, for example, for a closed-loop system in the medical industry.

Wet Solenoid

The Mac Valves Liquid BV with Wetted Solenoid is a solenoid valve that is used, among other things, for aggressive chemicals. The innovative design has been developed to dosage liquids precisely without membrane. Some materials do not mix easily with rubbers and some rubbers are only available as an o-ring.

Figure 9: Cross-section of Liquid Bullet Valve with Wetted Solenoid

If this is the case, you'll soon end up with the Wetted Solenoid version. In this design the liquid can reach the core, but it does not reach the coil. The valve is closed with o-rings and closes on an o-ring seat.

There is more dead space in this valve than in the other designs. On the other hand, if it is not a problem for the liquid, a broad range of choice can be made from metals, plastics and rubbers.

Liquid Valve Pump

Last but not least,, we arrived at the MAC Liquid Valve Pump. This valve is composed of techniques preceded by years of research and development. The unique and strong point of this pump is Microdosing.

Figure 10: Cross-section of a Liquid Valve Pump

Microliters are dosed per day by the combination of a short stroke with a small diameter. This is done with a high frequency. This way, substantial flow rates are achieved. As a result, the valve has been especially developed for the medical and petrochemical industry. Do you want to be able to mix, dose or fill very small quantities? The Liquid Bullet Valve Pump is ideal for this. The valve also generates a high output, because it is extremely precise and fast.

New developments…

We can already give you a glimpse of the new developments of our manufacturer. Meanwhile, the next electrically operated valve is already extensively tested. Moreover, this valve has not only been developed with a large bore, but also precise dosing without dead volume. In addition, we offer many more beautiful products. Not only innovation, but also quality is of paramount importance to our manufacturer.

Advice on buying Liquid Bullet Valves

Firstly, Astro Controls is happy to offer you personal advice and then develop MAC Valves your customized fluid valve. Together we look at the possibilities in terms of design. Realizing ambitious ideas? We love a challenge! Please contact us and request a demo or introduction meeting.